INVESTING IN AUTOMATION: COUNTERPART’S NEW STOPA CONNECTED TRUPUNCH 5000

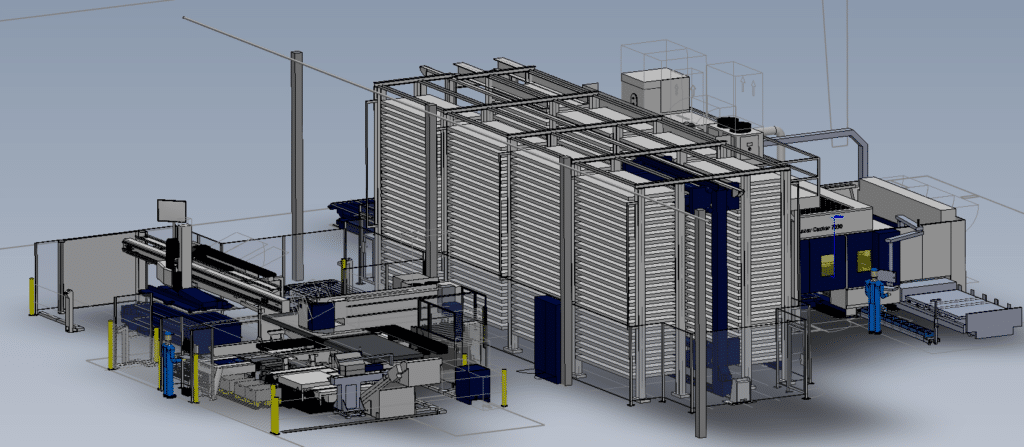

Here at Counterpart, Inc. we are continuing to invest in automation for increased production to best serve our customers. The first half of 2024 included the introduction of a brand new TRUMPF TruPunch 5000, which is our second machine connected to our STOPA; a large format storage system. This machine purchase included several options all geared towards successful unattended machine operation and the best utilization of available production time. Our new punch went online in July and has been producing quality parts ever since.

This machine, and storage automation, opens up significant new capacity, reduced manual labor requirements, improved part quality, and high-run capabilities. A big leap forward for our Laser Cutting Department.

AUTOMATION FOR INCREASED CAPACITY

STOPA Connection

The machine connection to STOPA allows us to build a list of production jobs such that the machine will finish one job and move right into the next, calling the correct material and unloading the pallets required. This automatic transition from one job to the next continues to promote uninterrupted operation.

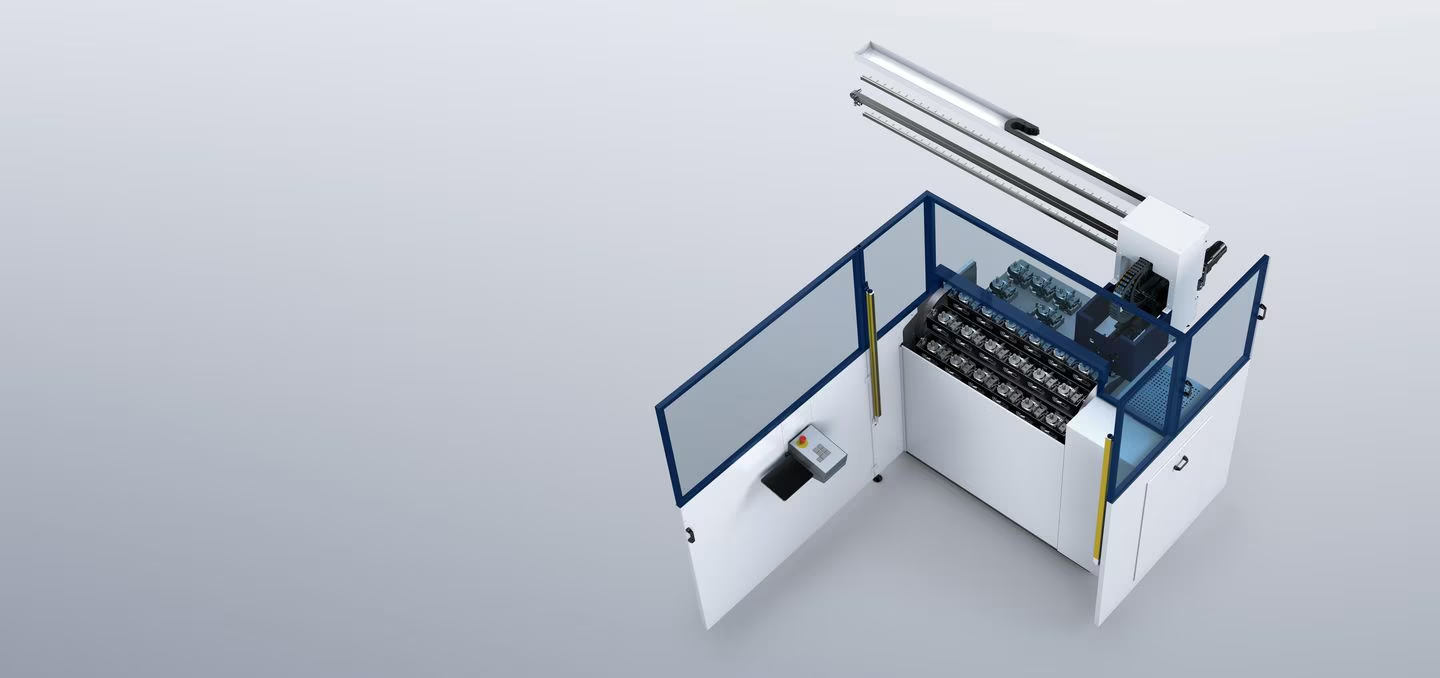

ToolMaster Linear

ToolMaster Linear

With the incorporation of an automatic tool changer, operators can access the changer parallel to production to insert new tools required for future jobs. This, once more, eliminates the need to stop the machine changing from one job to the next.

Skeleton Free Processing

When processing sheet metal, you typically have a skeleton in which the parts are cut out of that is left over as scrap. Normally, this is collected on a scrap table which has a limited stack height. Emptying the scrap table requires stopping the machine, entering the light curtain with a fork truck and hauling the scrap out to the dumpster, and then returning the scrap table to the machine. This is valuable production time wasted. Skeleton free processing allows us to utilize a scrap conveyor and the parts chute to chew up the sheet and convey it into a dumpster, parallel to production. The machine never has to stop.

These options and more are what give us confidence that this machine will produce 30% or MORE than our existing standalone Trumpf Punches. Counterpart, Inc’s 25+ years’ experience of punching, combined with the added technology of this new machine, equals a win-win for our customers!

Other Option

- Scratch Free Machining: The addition of brush tables and the optional scratch free machining improves the finish quality of parts produced on the TruPunch 5000.

- SortMaster Linear: The SortMaster Linear allows us to cut parts from the sheet and drop them into buckets sorting up to 4 different products from the same sheet. These parts drop down below the machine table onto a conveyor that then brings them to their designated sorting bin.

- SheetMaster Load/Unload: Though an option we already utilize on our existing machines, it’s important to note the ability to not only load raw materials automatically, but unload finished parts and palletize them for shipment or transfer to the next location in the shop.

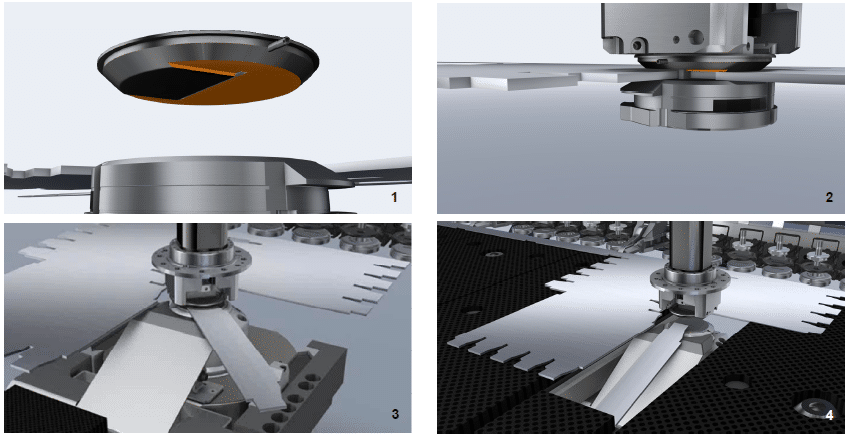

- Active Die: The introduction of active die allows us to actively move the die away from the sheet which prevents potential scratching of the bottom of the sheet. It also opens up the possibility of producing parts with formed features on the bottom of the sheet, vs. only the top of the sheet.

- Integrated Flattening: If you are familiar with punching perforated panels, you are familiar with the “oil can” effect that often occurs. Integrated flattening allows us to automatically back-bend the sheet so that your perforated panel comes out much flatter than conventional methods.

CONTACT US TODAY!

Contact Counterpart, Inc. today and find out how our manufacturing equipment can benefit YOU! Reach out on our CONTACT US page or by calling 605-692-5952. We are ready to serve your sheet metal needs!